- PolyJet Legacy Printers

- Alaris30 V1

- Connex260

- Connex350/500

- Eden250

- Eden260

- Eden260V/VS

- Eden330

- Eden350

- Eden350V/500V

- J700 & J720 Dental

- J750/J735

- J750 Digital Anatomy

- Objet24/30 V2 Family

- Objet24/30 V3 Family

- Objet30 V5 Pro & Prime

- Objet260 Connex 1-2-3

- Objet260 Dental & Dental Selection

- Objet350/500 Connex 1-2-3

- Objet1000 Plus

- PolyJet Materials

- Agilus30 family

- Biocompatible

- Biocompatible Clear MED610

- Dental Materials

- Dental TrueDent Materials

- Dental TrueDent-D Materials

- Digital ABS Plus

- DraftGrey

- Elastico Clear/Black

- High Temperature

- PolyJet Support

- Rigur & Durus

- Tango

- ToughONE™

- MED610-DSG

- Transparent

- Vero ContactClear

- Vero Family

- Veroflex

- VeroUltra Opaque

- Vivid Colors

- Stereolithography Materials

- Somos® 9120™

- Somos® BioClear™

- Somos® DMX SL™ 100

- Somos® Element™

- Somos® EvoLVe™ 128

- Somos® GP Plus™ 14122

- Somos® Momentum™

- Somos® NeXt™

- Somos® PerFORM™

- Somos® PerFORM Reflect™

- Somos® ProtoGen™ 18420

- Somos® ProtoTherm™ 12120

- Somos® Taurus™

- Somos® WaterClear® Ultra 10122

- Somos® WaterShed® AF

- Somos® WaterShed® Black

- Somos® WaterShed® XC 11122

- Somos® WaterShed® XC+

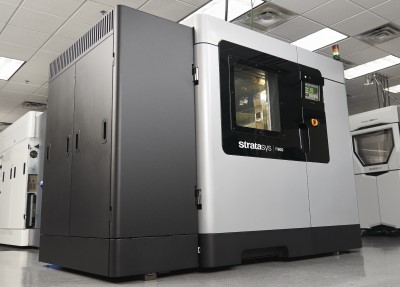

Fortus 900mc / F900 3D Printer

The Stratasys Fortus 900mc/F900 3D printing system incorporates the latest in innovative technologies to provide precision prototypes from a CAD design. Stratasys’ Fused Deposition Modeling (FDM) technology provides prototype parts, including internal features, that can be used to field-test form, fit, and function.

The Stratasys Fortus 900mc/F900 3D printing system has a vacuum platen is adapted for use with two build sheet sizes; The small sheet is 16 in. (40.6 cm) X 18.5 in. (47.0 cm) X 0.02 in. (0.05 cm) thick, and the large sheet is 26 in. (66.0 cm) X 38 in. (96.5 cm) X 0.02 in. (0.05 cm) thick. The envelope size is 36 in. (91.4 cm) wide X 36 in. high (91.4 cm) X 24 in. (60.96 cm) deep. The printer has four material bays; two for model and two for support.

- 50 Hz or 60 Hz

- 230VAC

- 40 Amp circuit

- 34 Amp full load current on all three phases

AC Power Requirements

- Required for communication and file transfer functions.

- Category 5 or better

- 10/100 Base T Ethernet, RJ45 connector.

LAN Requirements

Get a Quote for this Printer.

Buy Stratasys Materials and Service Consumables in Our Online Store

Service Contract Offering

Optimize your 3D printing with a service agreement -

seamless support, minimized downtime.

1:27

As Needed Maintenance - F900

5:34

How to Use TrueRefill on Fortus 450mc and F900mc

Featured Case Studies

General Motors Hemming - EN FDM Use Case

General Motors (GM) is a world leader in the development of transportation innovations that include electric cars and self-driving vehicle technology. Headquartered in Detroit, Michigan, GM serves six continents with 164,000 employees.

Find out General Motor reduced its cost by using 3D printing.

IDEC and Wehl - EN FDM Case Study

Aerospace Case Study: IDEC is a leading Spanish provider of composite solutions for the aerospace industry, servicing its customers’ design and manufacturing needs. With the help of advanced manufacturing service bureau, Wehl & Partner, the company embarked on a project to increase its competitiveness by reducing the time, cost and material waste of traditional composite molding.