Printers

- PolyJet Legacy Printers

- Alaris30 V1

- Connex260

- Connex350/500

- Eden250

- Eden260

- Eden260V/VS

- Eden330

- Eden350

- Eden350V/500V

- J700 & J720 Dental

- J750/J735

- J750 Digital Anatomy

- Objet24/30 V2 Family

- Objet24/30 V3 Family

- Objet30 V5 Pro & Prime

- Objet260 Connex 1-2-3

- Objet260 Dental & Dental Selection

- Objet350/500 Connex 1-2-3

- Objet1000 Plus

Materials

- PolyJet Materials

- Agilus30 family

- Biocompatible

- Biocompatible Clear MED610

- Dental Materials

- Dental TrueDent Materials

- Dental TrueDent-D Materials

- Digital ABS Plus

- DraftGrey

- Elastico Clear/Black

- High Temperature

- PolyJet Support

- Rigur & Durus

- Tango

- ToughONE™

- MED610-DSG

- Transparent

- Vero ContactClear

- Vero Family

- Veroflex

- VeroUltra Opaque

- Vivid Colors

- Stereolithography Materials

- Somos® 9120™

- Somos® BioClear™

- Somos® DMX SL™ 100

- Somos® Element™

- Somos® EvoLVe™ 128

- Somos® GP Plus™ 14122

- Somos® Momentum™

- Somos® NeXt™

- Somos® PerFORM™

- Somos® PerFORM Reflect™

- Somos® ProtoGen™ 18420

- Somos® ProtoTherm™ 12120

- Somos® Taurus™

- Somos® WaterClear® Ultra 10122

- Somos® WaterShed® AF

- Somos® WaterShed® Black

- Somos® WaterShed® XC 11122

- Somos® WaterShed® XC+

Displaced Drops

Displaced Drops on Model Surface

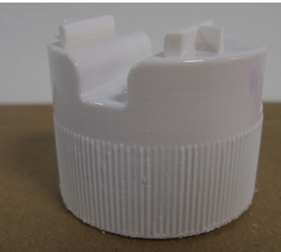

Sometimes displaced drops are formed on the surface of the model when printed with VeroUltra™ White material on J7 and J8 Series printers.

Possible Causes and Solutions

Air turbulence around the model

The air turbulence around the model does not occur in other materials because of different properties such as the weight of the drops, UV resistance, etc.

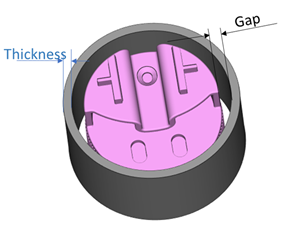

Solution 1: Cover the model with an external wall.

The recommended thickness is 2 mm and the gap from the model is 1 mm.

Preventive measures: Same as solution.

Solution 2: Print multiple models on the tray very closely.

The parts need to be approximately 1.0 mm apart to block the air turbulence.

Preventive measures: Same as solution.